HIGH PRECISION MACHINING

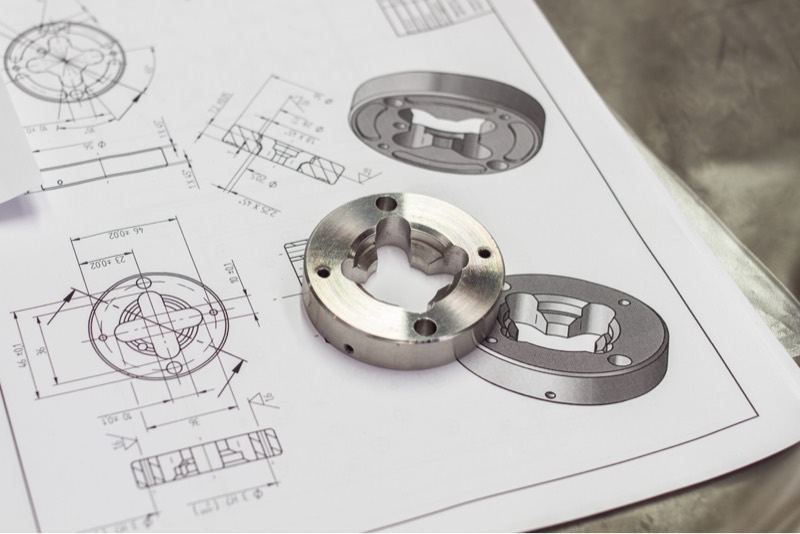

ADVANCED TECHNOLOGY IN MANUFACTURING AND DESIGN PROCESSES

Company

JYD Engineering, through its subsidiaries, supplies sub-contract precision engineering processes to a wide range of clients. Whether your needs are one-off prototype development work to large batch production components we have the equipment, staff and systems in place to fulfil your requirements under ISO 9001 and ISO 9100 quality standards. We have the CAD & CAM software and skills to manufacture parts through our comprehensive range of machining services.

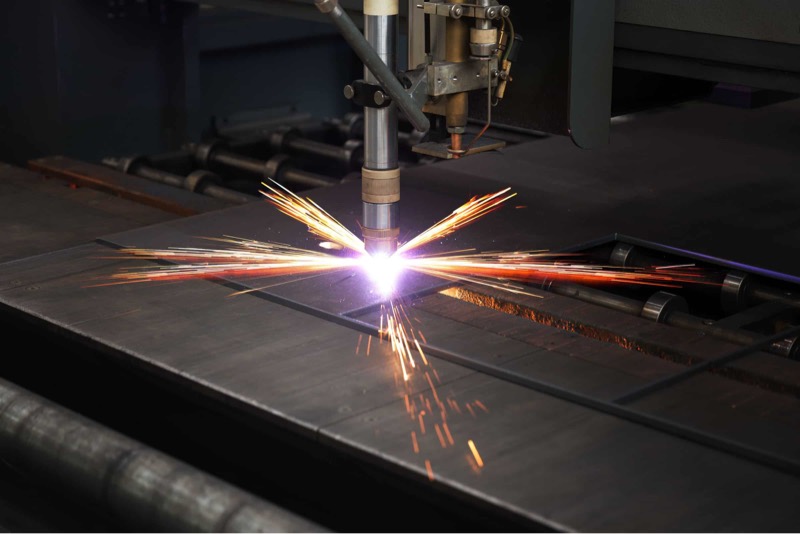

We use our leading edge CNC machines to create high-quality metallic and plastic components.

We are always looking to streamline our manufacturing procedures to maximise the efficiency of every job we undertake. With our modern machines and tools, our clients can be sure of the very best products, and of having them produced as efficiently as possible. We pride ourselves on being able to deliver a complete service, meeting all your manufacturing and assembly requirements.

History

Since our beginnings in 2007 we have developed a reputation for reliable and flexible manufacturing and been able to adapt to the changes of our industry, from the meticulous world of packaging we moved into the demanding aeronautical sector over the years; until reaching what we are today: a company that is committed to high precision machining using the most advanced technology. All this without changing the basic commitment of our raison d’être: to offer the customer the best solution, absolute reliability and total confidence in all our work.

Our extensive experience has allowed us to offer a wide range of products, from simple small and medium series machining to high precision machining to meet the most specific and demanding needs of our customers.

Process

Fulfilling our commitment to excellence and precision requires us to be up to date and to control every stage of the production process, from the management of raw materials to the final verification and inspection of the finished products. At the same time, we combine this meticulous monitoring and control with the identification of technological trends and an attitude of constant innovation and improvement that allows us to provide effective, efficient and reliable responses. A process for which we have software specifically created for the design, programming and verification processes of each of the phases.

1. Design

- CNC Programming

- CNC Verification

2. Manufacturing

- Milling in 3,4,5 axes

- Turning

- Wire-cutting EDM

3. Assembly and adjustment

- Reworking of aeronautical products

- Packaging dies

- Automotive dies

4. Quality

- Measurement by Romer Multigage Arm

- Three-dimensional measurement with DEA Mistral machine

- 100% dimensional control

- Three-dimensional reports with PC-Demis software

Sectors

Our track record and results have led us to work for the most demanding sectors of the market, such as aeronautics, automobile, naval, wind power, packaging and industrial. Sectors that require precise work and a capacity for constant adaptation and improvement.

Contact

For any enquiries or further information, please contact us on: info@jydengineering.com

Alternatively please complete the form below and press send and we will get back to you.